Pioneering Solutions That Matter

We work in partnership with industry to design, build, and deliver precision applications and equipment to solve complex and intricate manufacturing challenges.

Sherkin Technologies is a proven leader in the delivery of innovative processing solutions using Low Energy Electron Beam and Plasma Systems

We engage with customers to design, build, and support processing solutions to solve some of the most complex manufacturing challenges.

We have one goal in mind, customer satisfaction by pioneering solutions that matter.

Engage, listen, advise

With over 27 years experience in pioneering solutions in a wide range of sectors, let's start by discussing what you need and how we can help

Proof of Concept

We provide clients with the opportunity to engage in lab and pilot trials to allow them to evaluate the benefits of the technology.

Scaling and Manufacturing

We work with you to identify the best equipment that can achieve the performance and throughput in manufacturing, with the reliability and repeatability that production processes demand.

Full Support

We support you through the installation and commissioning process and follow-through with maintenance and servicing plans. All clients are assigned customer support accounts to help track support activities and provide access to system documentation and our extensive product knowledgebase.

EBLab 200

The next generation of Ebeam for the lab!

EBLab200 is an ideal system for in-house research and development of Ebeam processes.

Complete with all of the necessary tools and accessories to assist in the development of Ebeam curable inks and coatings, polymer and rubber crosslinking, grafting, and a wide range of other applications.

The EBLab200 is also a useful tool for quality control in production facilities.

Narrow Web Ebeam Systems

Narrow Web Ebeam systems are designed for narrow web applications up to 360mm wide with medium throughput.

Self-shielded and well engineered, these systems can be integrated in both pilot and production lines in printing, coating, crosslinking, grafting and a range of other installations.

Ebeam Engines

The building blocks for narrow web and 3D sample Ebeam processing.

Dedicated EBLamp, high voltage power supply, high voltage cable, and closed loop cooling system.

Wide Web Ebeam Systems

Ebeam systems for wider web installations deliver the throughput needed for industrial processing.

3 product lines service web widths and sheet fed processes:

- core 100, designed for curing lightweight coatings and inks on narrow webs

- Omnia, designed to fit a wide range of curing, laminating, and light crosslinking applications

- Invictus, the workhorse of ebeam processing equipment, used for the most demanding, high power applications.

In-House X-ray Systems

The eXede in-house X-ray system is the ideal solution for in-house sterilisation of high value product in boxes, bags, bottles, cannisters, pipes, trays, tubs, or just about any material handling configuration,

Regain control of you production process and schedules by bringing your product sterilisation process in-house with eXede.

Dosimetry

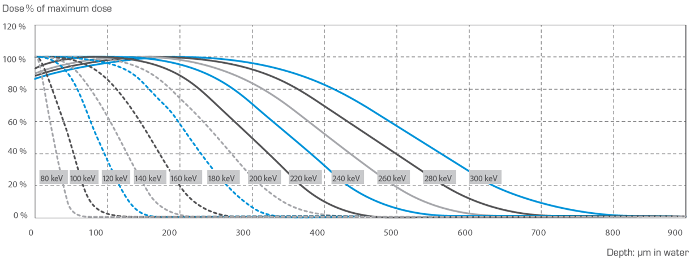

Dosimetry involves the determination of radiation dose by a combination of measurement and calculation.

Dosimetry is an important element in the ongoing monitoring and qualification of electron beam and X-ray machines.

Lab and Pilot Trials

Lab trials are a vital element in the evaluation of Ebeam technology. Concept and feasbility studies are performed on lab-scale equipment in order to assess the potential for Ebeam based processes to make an impact on a customer product or process.

Pilot line facilities allow potential customers to evaluate the scalability of an Ebeam process. The broader scale of Ebeam process parameters is invaluable in supporting the customer in their innovation journey.

Service and Support

We install, commission, service, and maintain equipment in academic and industrial sites.

Support begins at the trial stage and carries through during the machine build process, to FAT and beyond to the after sales support.

Consulting and Training

In many cases, Ebeam and Plasma processes are new to our customers.

Based on our experience over the past 28 years we can guide prospective customers in the evaluation, acquisition, deployment, operation and support of the equipment to deliver a timely return on their investment.

We are proud to work with

Creating breakthrough solutions that solve complex manufacturing challenges.

Knowledge, innovation, and expertise

Contact us today to schedule a meeting

We are ready to engage